Why do so many waste-to-energy plants fail?

Why in News?

The Kerala Government recently announced the State’s first Waste-To-Energy project in Kozhikode. The planned facility is expected to be built in two years and generate about 6 MW of power.

There are around 100 waste-to-energy projects around the country but only a handful of them are operational, thanks to various production and operation challenges.

What do Waste-to-Energy Projects do?

- Waste-to-energy projects use non-recyclable dry waste to generate electricity and ease Solid Waste Management (SWM)

- Solid waste in India is 55-60% biodegradable organic waste, which can be converted into organic compost or biogas; 25-30% non-biodegradable dry waste; and around 15% silt, stones, and drain waste.

- Of the non-biodegradable dry waste, only 2-3% – including hard plastics, metals, and e-waste – is recyclable.

- The remainder consists of low-grade plastic, rags, and cloth that can’t be recycled.

- This fraction of the non-recyclable dry waste is the most challenging portion of the present SWM system; the presence of these materials also reduces the efficiency of recycling other dry and wet waste.

- Waste-to-energy plants use this portion to generate power. The waste is combusted to generate heat, which is converted into electricity.

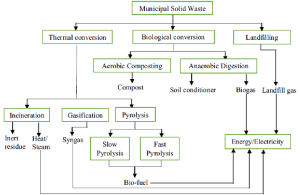

What is Waste-to-Energy Technologies?

- Biological Treatment Technologies (BTT): BTT is designed and engineered for natural biological processes working with the organic-rich fraction of Municipal Solid waste. These treatments are divided into two different processes:

- The aerobic process or composting (in the presence of oxygen) and the anaerobic process (in the absence of oxygen).

- Thermal Treatment Technologies: The thermal treatment of hazardous waste involves pyrolysis, gasification, and incineration techniques, depending upon the nature of the waste and the end-product application.

- Pyrolysis is the heating of an organic material, such as biomass, in the absence of oxygen. Biomass pyrolysis is usually conducted at or above 500 °C, providing enough heat to deconstruct the strong biopolymers.

- Gasification is a process that converts organic or fossil-based carbonaceous materials at high temperatures (>700°C), without combustion, with a controlled amount of oxygen and/or steam into carbon monoxide, hydrogen, and carbon dioxide.

- Incineration is a rapid oxidation process, which is used to convert VOCs (Volatile Organic Compounds) and other gaseous hydrocarbon pollutants to carbon dioxide and water.

- Torrefaction converts biomass in the absence of oxygen at a temperature of 200–300°C to produce torrefied materials, bio-oils, biochar, etc.

What are the Challenges Related to Such Plants?

- Low Calorific Value: The low calorific value of solid waste in India due to improper segregation. The calorific value of mixed Indian waste is about 1,500 kcal/kg, which is not suitable for power generation.

- The calorific value of segregated and dried non-recyclable dry waste is much higher, at 2,800-3,000 kcal/kg, sufficient to generate power. However, segregation should be streamlined to ensure the waste coming to the facility has this calorific value.

- High Costs of Energy Production: The cost of generating power from waste is around Rs 7-8/unit, while the cost at which the States’ electricity boards buy power from coal, hydroelectric, and solar power plants is around Rs 3-4/unit.

- Improper Assessments: Many waste-to-energy projects have failed because of improper assessments, high expectations, improper characterisation studies, and other on-ground conditions.

What can be the Solution?

- While State electricity boards are considering purchasing power from newer renewable energy sources like waste-to-energy, the price of the power generated needs to halve.

- Setting up waste-to-energy projects is complex and needs the full support of the municipality, the State and the people. To overcome its various challenges, the municipality must ensure that only non-biodegradable dry waste is sent to the plant and separately manage the other kinds of waste.

- Importantly, the municipality or the department responsible for SWM should be practical about the high cost of power generation, and include the State electricity department, perhaps as a tripartite agreement between the municipality, the plant operator, and the power distribution agency.

- It is also crucial to conduct field studies and learn from the experience of other projects.

- Without all these efforts, the project may not be a success, which in turn will stress the State Government to manage all the accumulated waste, which can be a costly mistake.